Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

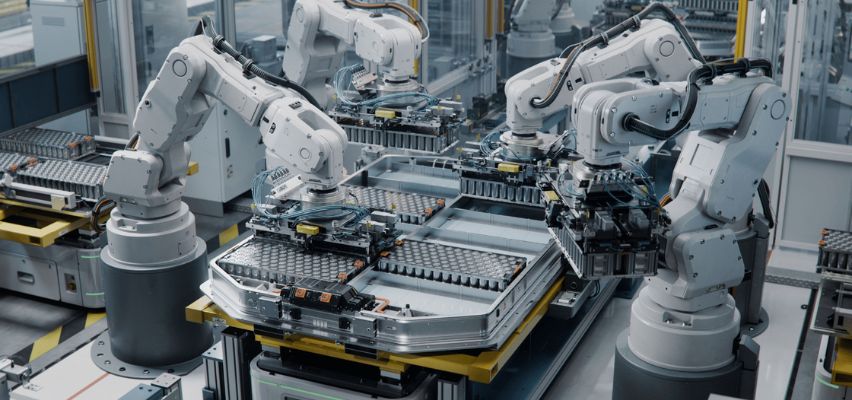

Global lithium-ion battery production is set to expand nearly fivefold between 2021 and 2030, reaching about 5,500 GWh. Within this growth, electric vehicle (EV) batteries will account for almost 80% of total output, underscoring the scale of change shaping the mobility sector worldwide.

This growth presents both opportunities and pressing challenges:

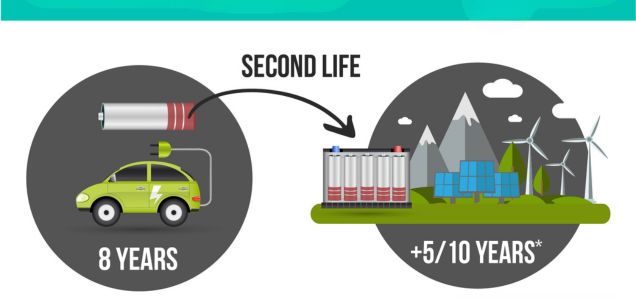

Recycling is no longer optional it is a strategic priority for ensuring supply chain resilience and long term industry growth.

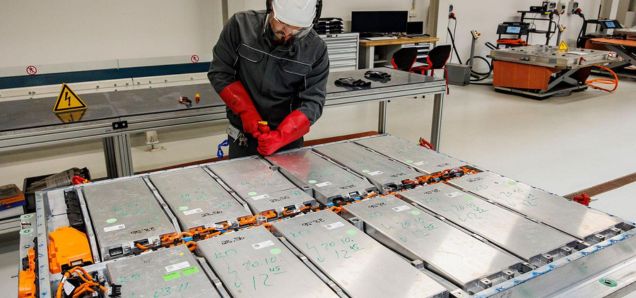

The production of lithium-ion batteries generates up to 40% manufacturing scrap, while nearly 2 million tons of end-of-life batteries are expected to enter recycling streams by 2030. Effectively capturing these resources is vital to:

Among today’s recycling technologies, solvent extraction (SX) stands out as one of the most effective and scalable methods for recovering valuable materials from lithium-ion batteries. Its proven advantages include:

These strengths position solvent extraction as a cornerstone solution for the global battery recycling industry.

Since 2014, Ganzhou Highpower Technology has relied on Escaid™ diluents in its EV battery recycling operations. Reported benefits include:

The company continues to recommend Escaid fluids as a reliable and high-performance solution for solvent metal extraction.

In Europe, strict EU recycling directives are driving companies to adopt solvent extraction to ensure compliance and maintain secure access to nickel and cobalt — metals that are critical for the region’s EV market.

Across the U.S. and Canada, SX-based recycling is strengthening domestic supply chains by enabling recovery of essential materials. This reduces reliance on imports and contributes to long-term energy security.

With the rapid growth of EVs, recycling of lithium-ion batteries is essential for sustainability and supply security. Solvent extraction (SX) offers high recovery rates, superior purity, and safer operations, making it a key solution for building resilient, circular supply chains worldwide.